Clean water is something many people take for granted yet behind every glass of safe drinking water is a complex and carefully managed water treatment plant. These facilities play a critical role in protecting public health, supporting industries, and sustaining ecosystems. To operate effectively, every water treatment plant relies on a set of essential components, processes, and practices that work together to ensure water quality and reliability.

- Source Water Intake and Screening

- Coagulation and Flocculation Systems

- Sedimentation and Clarification

- Filtration Technologies

- Disinfection Systems

- Sludge and Residuals Management

- Monitoring, Automation, and Control Systems

- Skilled Operators and Maintenance Practices

- Infrastructure and Emergency Preparedness

- In Conclusion

Source Water Intake and Screening

The treatment process begins with source water, which may come from rivers, lakes, reservoirs, or groundwater. Intake structures are designed to collect water efficiently while minimizing the entry of debris, sediment, and aquatic organisms. Screens and grates serve as the first line of defense, removing large objects such as leaves, trash, and sticks that could damage equipment or disrupt operations. Properly designed intake systems help stabilize flow rates and protect downstream treatment processes.

Coagulation and Flocculation Systems

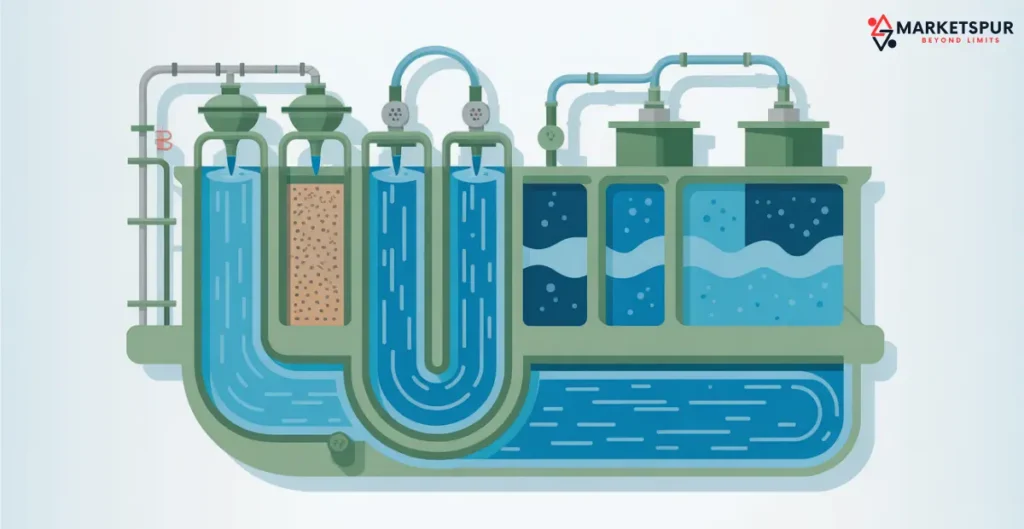

Once water enters the plant, it undergoes coagulation and flocculation two foundational steps in removing suspended particles. During coagulation, chemicals are added to neutralize the electrical charges of fine particles, allowing them to clump together. Flocculation gently mixes the water, encouraging these particles to form larger clusters known as floc. These systems must be carefully controlled, as proper mixing speed, timing, and chemical dosing are essential for effective particle removal.

Sedimentation and Clarification

After flocculation, water flows into sedimentation or clarification basins. Here, gravity does the work by allowing heavier floc particles to settle at the bottom of the tank. This step significantly reduces turbidity and removes a large portion of impurities before filtration. Well designed sedimentation basins improve overall plant efficiency, reduce filter loading, and lower operational costs over time.

Filtration Technologies

Filtration is one of the most critical stages in water treatment. Filters remove remaining fine particles, microorganisms, and other contaminants that were not captured during sedimentation. Common filtration methods include sand filters, multimedia filters, and membrane systems. In advanced applications, specialized media such as nanoporous carbon powder may be used to enhance adsorption and remove trace organic compounds. Regular backwashing and monitoring are essential to maintain filter performance and extend equipment life.

Disinfection Systems

Even after filtration, water must be disinfected to eliminate harmful bacteria, viruses, and parasites. Disinfection methods vary but commonly include chlorine, chloramine, ozone, or ultraviolet (UV) light. Each method has its advantages, and many plants use a combination to ensure effectiveness while minimizing byproducts. Proper disinfection is crucial for meeting regulatory standards and ensuring water remains safe throughout the distribution system.

Sludge and Residuals Management

Water treatment inevitably produces waste materials, including sludge from sedimentation and backwash water from filters. Effective sludge handling systems are essential for plant cleanliness, regulatory compliance, and environmental protection. This may involve thickening, dewatering, and proper disposal or reuse of residuals. Efficient residuals management not only reduces operational challenges but also lowers long term environmental impact.

Monitoring, Automation, and Control Systems

Modern water treatment plants rely heavily on instrumentation and automation. Sensors monitor parameters such as pH, turbidity, chlorine levels, and flow rates in real time. Automated control systems allow operators to adjust processes quickly, respond to changes in water quality, and optimize chemical usage. Reliable monitoring ensures consistent performance, improves efficiency, and supports compliance with safety regulations.

Skilled Operators and Maintenance Practices

Even the most advanced treatment plant depends on knowledgeable staff. Trained operators are essential for interpreting data, responding to alarms, and making informed decisions during routine operations or emergencies. Preventive maintenance programs keep equipment running smoothly, reduce downtime, and extend the lifespan of critical assets. Regular inspections, calibration, and staff training are key components of a resilient facility.

Infrastructure and Emergency Preparedness

Finally, robust infrastructure and contingency planning are essential for long term success. Backup power systems, redundant pumps, and emergency response plans help ensure uninterrupted service during power outages, natural disasters, or equipment failures. Planning for growth and climate related challenges also helps plants adapt to future demands while continuing to deliver safe water.

In Conclusion

Water treatment plants are the backbone of clean and safe water delivery. From intake and filtration to disinfection and monitoring, each essential component plays a vital role in protecting public health. By investing in reliable systems, skilled personnel, and proactive maintenance, water treatment plants can continue to provide the clean water that communities depend on every day.